by Donald E. Powers, PTR-Precision Technologies, Enfield, CT USA

A glimpse is given of how electron beam welding has evolved in the United States over five decades.

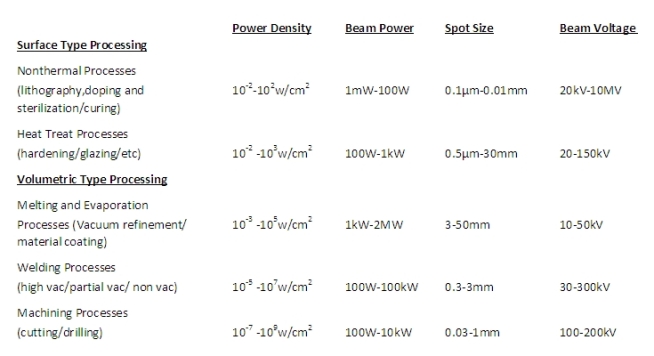

Using an electron beam (EB) to perform material processing tasks first began in the early l900's to melt refractory metals in vacuum. Since then, its utilization for processing other forms of material has steadily increased as the level of capability of its two main supporting technologies, vacuum engineering and electron optics, have continued to evolve and mature with time. Thus, as shown in Table 1, its present day use in the area of industrial material processing covers a broad range of applications -- varying in nature from tasks that employ a very low power density beam (very shallow, surface types) to those that employ a very high power density beam (very deep, volumetric types).

The application of EB to the task of welding (EBW) was initiated in Germany during the early 1950s, then spread to France by the mid-50s. Shortly thereafter, and before the end of that decade, use of the process was introduced into the United States with the purchase of an EBW unit from Germany by Westinghouse's Bettis plant. This occurred in response to articles the French Atomic Energy Commission had published outlining its successful utilization of the EBW process to join components being used by the nuclear energy industry.

EBW Process Fundamentals

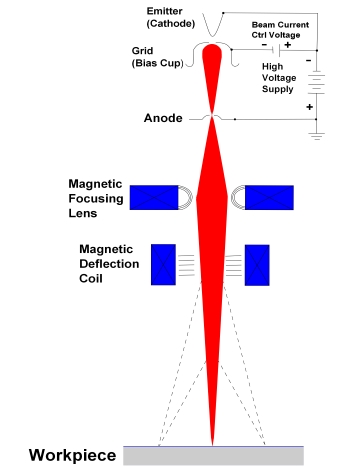

A schematic representation on the type of EB gun and column assembly commonly employed to perform EB welding tasks is shown in Fig. 1. This figure illustrates a triode style (cathode, grid, and anode) gun being used to generate the beam, as well as the electron optical (focusing and deflection) system utilized for controlling the manner (final beam spot size produced and its positioning) in which this beam is then impinged on the workpiece. In operation, the cathode, an emitter that can be either directly or indirectly heated, provides a source of thermally emitted electrons that are simultaneously accelerated and shaped into a collimated beam by the electrostatic field geometry produced by the gun grid, anode configuration being employed, and then focused into a highly intense beam spot on the workpiece.

A schematic representation on the type of EB gun and column assembly commonly employed to perform EB welding tasks is shown in Fig. 1. This figure illustrates a triode style (cathode, grid, and anode) gun being used to generate the beam, as well as the electron optical (focusing and deflection) system utilized for controlling the manner (final beam spot size produced and its positioning) in which this beam is then impinged on the workpiece. In operation, the cathode, an emitter that can be either directly or indirectly heated, provides a source of thermally emitted electrons that are simultaneously accelerated and shaped into a collimated beam by the electrostatic field geometry produced by the gun grid, anode configuration being employed, and then focused into a highly intense beam spot on the workpiece.

Use of a triode style gun allows, at any fixed operating voltage, the magnitude of electron flow exiting the gun (i.e., the beam operating current, and thus the resulting beam power being delivered to the workpiece) to readily be adjusted as desired. Thus, by simply varying the negative potential difference being applied between cathode and grid, the beam can easily be either instantaneously turned on/off or have its operating level ramped up/down in a highly controlled fashion. In addition to providing the ability to produce either a highly focused or slightly defocused beam spot on the workpiece, the electron optical system employed also provides the capacity for deflecting the beam spot in either a static (fixed positional change) or dynamic (oscillatory positional change) fashion.

In contrast to more conventional conductive means of welding, the main joining advantage EBW provides users is the ability to perform what is commonly referred to as "keyhole welding", illustrated in Fig. 2. In keyhole welding, the highly intense beam impinged on the workpiece generates a vapor channel that penetrates into the workpiece. This allows the beam's energy to be delivered directly to the weld joint faying surfaces deep down inside the workpiece, rather than simply being deposited onto its top surface, as in the case of more conventional welding methods. As this vapor channel is advanced, molten metal being formed at its leading edge continuously flows around it, solidifying behind its trailing edge to form the final weld joint.

In contrast to more conventional conductive means of welding, the main joining advantage EBW provides users is the ability to perform what is commonly referred to as "keyhole welding", illustrated in Fig. 2. In keyhole welding, the highly intense beam impinged on the workpiece generates a vapor channel that penetrates into the workpiece. This allows the beam's energy to be delivered directly to the weld joint faying surfaces deep down inside the workpiece, rather than simply being deposited onto its top surface, as in the case of more conventional welding methods. As this vapor channel is advanced, molten metal being formed at its leading edge continuously flows around it, solidifying behind its trailing edge to form the final weld joint.

The 1960s thru mid-l980s

Once introduced into the United States, interest in the EBW process quickly grew. Numerous EB symposiums, seminars, and conferences were held in the early 1960s, providing attendees with a continuous source of information about the process from both U.S. and foreign users and manufacturers. Concurrently, various suppliers of the equipment began exhibiting at the welding shows. The combination of these two events strongly contributed to the rapidly expanding interest the U.S. welding community had in both the EBW process and its growing use by industry.

![]()

Table 1 - Overview on Various Uses for Industrial Processing

During the early 1960s, it was established that the deep penetration results provided by the keyhole form of welding achieved with EB depended primarily on the magnitude of beam power density being employed rather than the level of operating voltage utilized, and a variety of U.S. based companies became involved with manufacturing EBW equipment having operating voltages spanning the full range from 25 to 150 kV. The list of these companies included Nuclide, National Research, Hamilton Standard, and Sciaky to name just a few. Before the end of the 1960s, however, many of these companies discontinued this manufacturing practice, leaving Hamilton Standard and Sciaky as the two leading U.S. based producers of EBW equipment - a position both still hold today, although each has since changed ownership several times.

The Golden Years

The 1960s were unquestionably the golden years for EB welding in the United States. During this ten-year period alone some 500 EBW machines, more than a third of the total number of units installed over the past 50-plus years, were installed in the United States. In addition, while the EBW units installed during the early 1960s mainly had relatively small high-vacuum chambers with very limited workpiece motion and beam power output capability, those being supplied by the mid-1960s consisted of units having fairly large high-vacuum chambers with the capacity to provide both multiaxis workpiece and/or gun motion, as well as beam power outputs ranging up to 45 kW. At about the same time, units with the ability to apply the process under both partial vacuum and nonvacuum conditions, as well as high vacuum, were introduced concurrent with units that additionally employed both CNC-operated workpiece motion and beam parameter control.

EBW Shows lts Versatility

During the 60s, EBW became a multi-mode welding process viewed as having potential applications for virtually any type of joining task imaginable, including a metal dress produced from aluminum foil and mesh materials to highlight the joining versatility of the process. This resulted in the development of a number of fairly innovative means and methods for expanding the EBW process' scope of application during that decade.

A few examples follow:

- The Perforated Wall Hollow Cathode. A cold cathode device for generating electron beams that could be configured into annular, cylindrical, and spherical shapes one form of which provided a fairly simple device for use in joining tubular components in a belljar style of environment.

- Hand-Held EB Gun. A device developed for NASA astronauts to use for both fabrication and repair type welding in space.

- Portable EBW Pipe Welding Machine. A system produced for the AGA that employed a crane-supported, C-clamp style high-vacuum chamber containing a trolley-driven, right-angle EB gun for use in providing 360-deg peripheral welds on pipe segments in the field.

- Clam-Shell Style EBW System. A unit delivered to Grumman Aerospace for welding the large moving structure components used in the manufacture of the Grumman F-14 TOMCAT fighter aircraft.

![]()

Other products of the 1960s included the adaptation of nonvacuum EB to tube mills, which provided the capacity to perform high-speed out-of-vacuum tube welding that was continuously being formed directly from strip material. Another was the employment of individually pumped pre-high-vacuum and post-high-vacuum pressure stages, separated by apertures that allowed the constant passage of the dual strip material being joined in high vacuum. This provided the ability to weld the bimetal product being utilized by the saw blade industry in a continuous air-to-air fashion.

A Shift in the 1970s

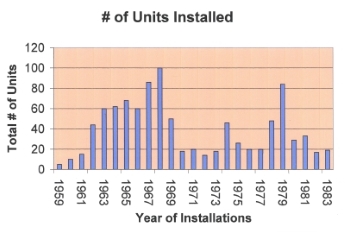

Annual EBW machine installations in the United States, which had reached a peak of about 100 units per year before the end of the 1960s, began a noticeable decline by the start of the 1970s. This resulted from a saturation of EBW equipment in the primary markets of that era, the aerospace, medical, aeronautical, and AEC-DOE industries. However, during the 1960s, the U.S. automotive industry became quite interested in the various joining advantages EBW might offer it if the production welding capacity of the process could be greatly increased. Batch loading methods were initially employed to help increase the number of parts capable of being processed each time the weld zone environment had to be evacuated to a high-vacuum level. Then, as the partial vacuum and nonvacuum modes of EBW application matured with use during the 1960s, much greater production rate capacities were made available since both these modes of EBW application either appreciably reduced or entirely eliminated any production time that would be lost loading parts into a high vacuum environment.

Thus, with a growing number of EBW machine sales being made to the auto industry starting in the late 1960s and extending out through the 1970s, annual EBW machine installations in the U.S. again began approaching the 100 level. However, a series of events originating toward the close of the 1970s (problems in the auto industry, a general sagging economy, and the advent of laser beam welding [LBW] as a competitor) once again contributed to a decrease in this number by the start of the 1980s - Fig. 3.

Thus, with a growing number of EBW machine sales being made to the auto industry starting in the late 1960s and extending out through the 1970s, annual EBW machine installations in the U.S. again began approaching the 100 level. However, a series of events originating toward the close of the 1970s (problems in the auto industry, a general sagging economy, and the advent of laser beam welding [LBW] as a competitor) once again contributed to a decrease in this number by the start of the 1980s - Fig. 3.

The makeup of suppliers of EBW equipment to the U.S. market also began changing during the 1970s. Foreign manufacturers of the equipment (Steigerwald, TorrVac, and Wentgate) started entering the marketplace by licensing various U.S.-based companies originally involved with manufacturing EBW equipment, but that had discontinued that practice and started up EBW job shops to act as their sales representatives. Several new U.S. based suppliers (Union Carbide and Westinghouse) also entered the market at about the same time, thereby providing Sciacky and Hamilton Standard with a variety of new competitors for EBW machine sales.

![]()

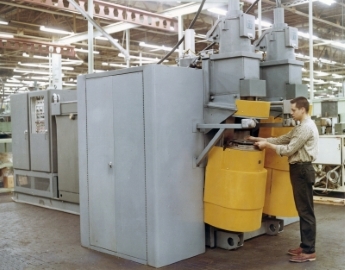

With the auto industry being the primary U.S. procurer of EBW equipment in the 1970s, the majority of EBW units installed during that decade were either of the partial vacuum (PVEBW) or nonvacuum (NVEBW) variety. Two of the very earliest ones delivered to the auto industry, the drop-bottom style PVEBW flywheel welding machine (Fig. 4) supplied to Ford and the carousel-style NVEBW steering column jacket machine supplied to GM, were each installed and made fully operational by the very early 1970s. Before the mid-1970s, numerous drop-bottom styles, including sliding seal variety PVEBW and drop-bottom style, room variety NV-EBW units had been delivered to the auto industry, providing several auto plants with as many as 10 to 20 EBW units operating in production by the middle of that decade.

With the auto industry being the primary U.S. procurer of EBW equipment in the 1970s, the majority of EBW units installed during that decade were either of the partial vacuum (PVEBW) or nonvacuum (NVEBW) variety. Two of the very earliest ones delivered to the auto industry, the drop-bottom style PVEBW flywheel welding machine (Fig. 4) supplied to Ford and the carousel-style NVEBW steering column jacket machine supplied to GM, were each installed and made fully operational by the very early 1970s. Before the mid-1970s, numerous drop-bottom styles, including sliding seal variety PVEBW and drop-bottom style, room variety NV-EBW units had been delivered to the auto industry, providing several auto plants with as many as 10 to 20 EBW units operating in production by the middle of that decade.

The 1970s also produced a number of changes in the nature of the EBW units being supplied. Although EBW manufacturers had previously been providing units to the aerospace, nuclear, and other industries with systems that were quite satisfactory for their applications, once EBW equipment suppliers began providing units to the auto industry they quickly learned that the systems had to be suitable for continuous operation (i.e., 24 hours a day, 7 days a week) during peak production months. Consequently, EBW equipment manufacturers were obligated to incorporate numerous equipment design and process performance improvements during the 1970s. At the same time, manufacturers also had to start replacing analog with digital-style controls in order to meet the auto industry's growing requirement for a higher degree of operating flexibility and a greater ease of equipment serviceability. As a result, by the start of the 1980s, most of the EBW equipment being provided to the U.S. market employed some form of digital-style controls.

The mid-1980s to Present

Since EBW equipment being made available to the U.S. market by the mid-1980s had been appreciably enhanced over that which had been available during the 1960s and 1970s, and with most all suppliers of EBW units by then providing systems with PLC and/or CNC system controls, solid-state control modules, improved beam current, and deflection pattern control capabilities, as well as optionally offering joint tracking, data acquisition, and beam diagnostic packages, the cost of purchasing an EBW unit had increased significantly. Thus, with the state of the economy at that time and the tighter restrictions being placed on the purchase of capital equipment as a result of these poor economic conditions, the decrease in annual new machine sales that had begun near the start of the 1980s continued on throughout that entire decade.

However, with an installed base of better than 800 EBW units already in place in the United States by the beginning of the 1980s, the market was somewhat bolstered by an increase in the sales of customer support functions (field service, spare parts, and accessories), as well as by a new avenue for equipment sales that had begun opening up by then. This was the sale of "upgrade packages" (i.e., retrofit, refurbishment, and modernization kits) for existing equipment, an area that provided a good potential for sales since more than half the EBW units in the existing installed machine base were 1960s vintage units. Upgrade packages being offered consisted of such major items as PLC or CNC machine control changeovers and beam generation system changeovers, the major type of machine makeovers that could generally be funded through an existing maintenance budget, rather than requiring authorization for a capital equipment expenditure.

This market for upgrades continues to provide an area of good sales opportunity even today, as present day estimates indicate that some 900 to 1000 of the roughly 1400 to 1500 EBW units installed in the United States during the past 50-year period (~75%) continue to remain in use today, either at the original purchaser's facility or at the facility of the second or third (and even subsequent) owner of the unit. Several hundred of these units still in use today (~30%) are either 1960 or 1970 vintage systems.

![]()

The Growth of Job Shop EBW

Another area of business initiated by the increased cost involved with purchasing a new EBW system by the 1980s was that of performing contract, job shop EB welding. This was due to the fact that this form of EBW business offered potential users of the process, those generally interested in applying it to their product but are unable to achieve the level of machine time utilization necessary to justify the outright purchase of an EBW system, the opportunity to economically outsource EB welding tasks to an EB job shop. This job shop EB welding business has continued to expand with time, and, as indicated by Fig.5, there are presently more than 50 EB job shops in operation across the United States. The majority of these shops are located on the East and West coasts, primarily in California and New England. These facilities range in size from small ones having as few as one or two EBW units in operation up to large ones with as many as five to ten units in operation. Included in this are several EB job shop welding businesses being operated by both the leading U.S. based EBW equipment providers, PTR (formerly Hamilton/Leybold) and Sciacky.

Another area of business initiated by the increased cost involved with purchasing a new EBW system by the 1980s was that of performing contract, job shop EB welding. This was due to the fact that this form of EBW business offered potential users of the process, those generally interested in applying it to their product but are unable to achieve the level of machine time utilization necessary to justify the outright purchase of an EBW system, the opportunity to economically outsource EB welding tasks to an EB job shop. This job shop EB welding business has continued to expand with time, and, as indicated by Fig.5, there are presently more than 50 EB job shops in operation across the United States. The majority of these shops are located on the East and West coasts, primarily in California and New England. These facilities range in size from small ones having as few as one or two EBW units in operation up to large ones with as many as five to ten units in operation. Included in this are several EB job shop welding businesses being operated by both the leading U.S. based EBW equipment providers, PTR (formerly Hamilton/Leybold) and Sciacky.

New Offerings

In the 1990s, EBW equipment suppliers began to offer more moderately priced, scaled-down systems (Fig. 6A) as an alternative to the highly specialized, high-expense systems (Fig. 6B). These more compact and cost effective units were generally of the low-voltage variety with a beam power output capacity of 15kW, or under. Most, however, continued to provide their users with all the same equipment enhancements present on the larger and more expensive units. Purchasers of EBW equipment since the early 1990s were thereby provided with the choice of a full range of high- to low-voltage, high-vacuum, partial vacuum, and non-vacuum high to low power units that are high and moderately priced. The use of EBW equipment was also expanded during the 1980s and 1990s to include tasks other than welding such as surface treatment (hardening, glazing, and texturing), brazing, and free form style fabrication (near-net-shape and additive manufacturing). Concurrently, the equipment was also shown to have the optional capacity of supplying users with computer enhanced beam diagnostic images and the ability to perform "simulated" multi-beam processing tasks.

In the 1990s, EBW equipment suppliers began to offer more moderately priced, scaled-down systems (Fig. 6A) as an alternative to the highly specialized, high-expense systems (Fig. 6B). These more compact and cost effective units were generally of the low-voltage variety with a beam power output capacity of 15kW, or under. Most, however, continued to provide their users with all the same equipment enhancements present on the larger and more expensive units. Purchasers of EBW equipment since the early 1990s were thereby provided with the choice of a full range of high- to low-voltage, high-vacuum, partial vacuum, and non-vacuum high to low power units that are high and moderately priced. The use of EBW equipment was also expanded during the 1980s and 1990s to include tasks other than welding such as surface treatment (hardening, glazing, and texturing), brazing, and free form style fabrication (near-net-shape and additive manufacturing). Concurrently, the equipment was also shown to have the optional capacity of supplying users with computer enhanced beam diagnostic images and the ability to perform "simulated" multi-beam processing tasks.

Summary

During more than a 50-year period, EB welding in the United States has gradually evolved from being a highly unique laboratory tool initially considered of interest primarily to the nuclear and aerospace industries, to a highly sophisticated production tool that is now utilized, to some degree, by most segments of U.S. industries. Thus, its present-day industrial usage spans a range of applications that provide highly expensive components (with fairly minimal production rate requirements) for aerospace, and nuclear industries to relatively low expense components (with very high production rate requirements) for the auto and tool industries. Consequently, during these years, EBW has steadily grown to be a process that provides users with a highly reliable manufacturing procedure that has readily demonstrated its capacity to accomplish tasks of both the shallow surface variety and the deep penetration type. It is a process that, given the ongoing advancements being made in the areas of beam generation, control and deflection technology, will continue to grow in application capability well into the future.

During more than a 50-year period, EB welding in the United States has gradually evolved from being a highly unique laboratory tool initially considered of interest primarily to the nuclear and aerospace industries, to a highly sophisticated production tool that is now utilized, to some degree, by most segments of U.S. industries. Thus, its present-day industrial usage spans a range of applications that provide highly expensive components (with fairly minimal production rate requirements) for aerospace, and nuclear industries to relatively low expense components (with very high production rate requirements) for the auto and tool industries. Consequently, during these years, EBW has steadily grown to be a process that provides users with a highly reliable manufacturing procedure that has readily demonstrated its capacity to accomplish tasks of both the shallow surface variety and the deep penetration type. It is a process that, given the ongoing advancements being made in the areas of beam generation, control and deflection technology, will continue to grow in application capability well into the future.

Page 5