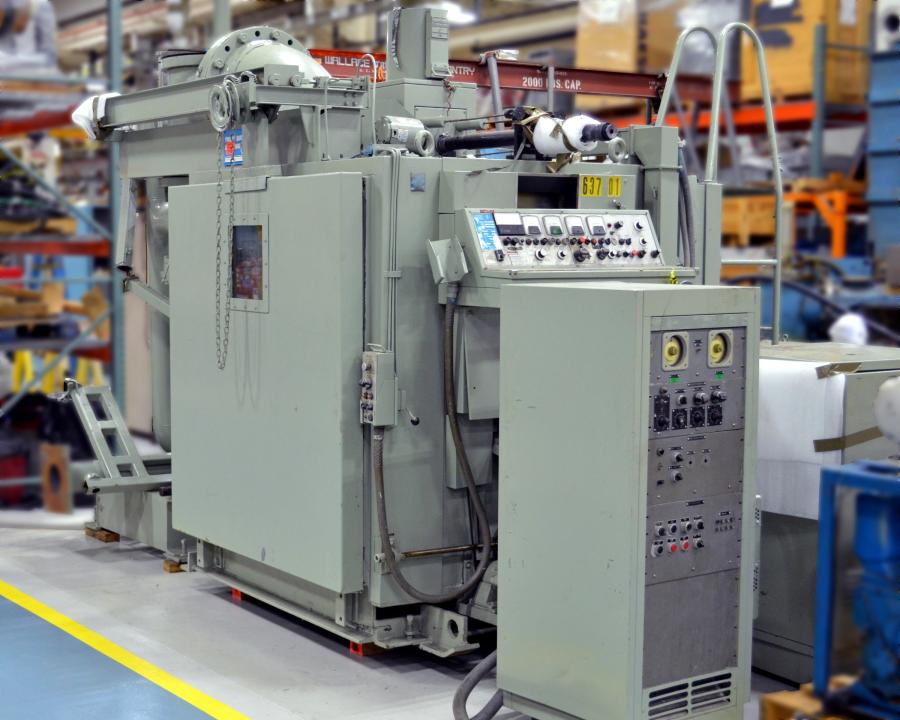

Hamilton Standard W2 Electron Beam Welder

This Hamilton Standard W2 EB welding system would require futher upgrading with new components- and can be retrofitted with either a new 150kV, or 60kV beam generation system. Currrently this unit has a new operator console, electrical cabinet and Fanuc CNC system control that were all upgraded in 2020.

CHAMBER SIZE:

62/74" Long x 62" Wide X 64" High

X-Y WORK TABLE:

X- and Y-axis table assembly 33" long by 17" wide with strokes of 33" in the X-axis and 16" in the Y-axis. The table is capable of supporting 2,500 pounds.

TABLE RUNOUT SYSTEM:

Powered runout assembly for X - Y motion system.

Contact Us For Further Details