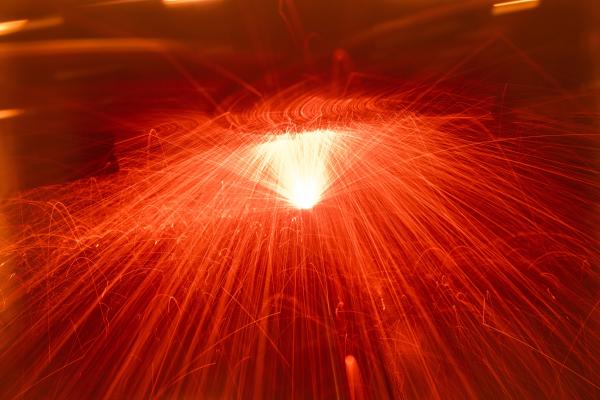

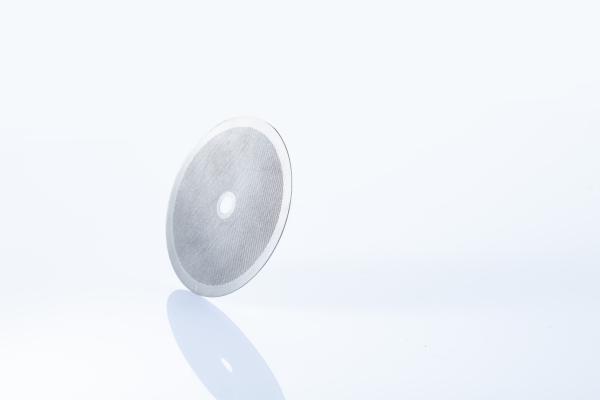

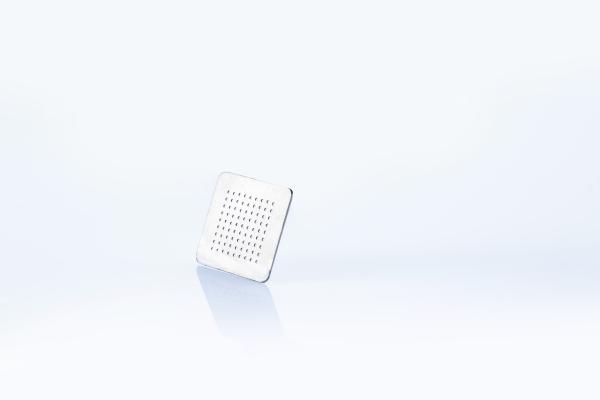

Do you have an application that requires tens of thousands, or even millions of holes? Using the electron beam for processing enables fast and accurate through-hole drilling in workpieces due to densely focused, high kinetic energy as well as high-speed control of the electron beam itself. Should you have a specific project, 1-time requirement, or general interest in establishing a contract drilling relationship then please reach out for further discussion.

Contact:

PTR Sales Department

Phone: (860) 741-9355

Email: sales@ptreb.com