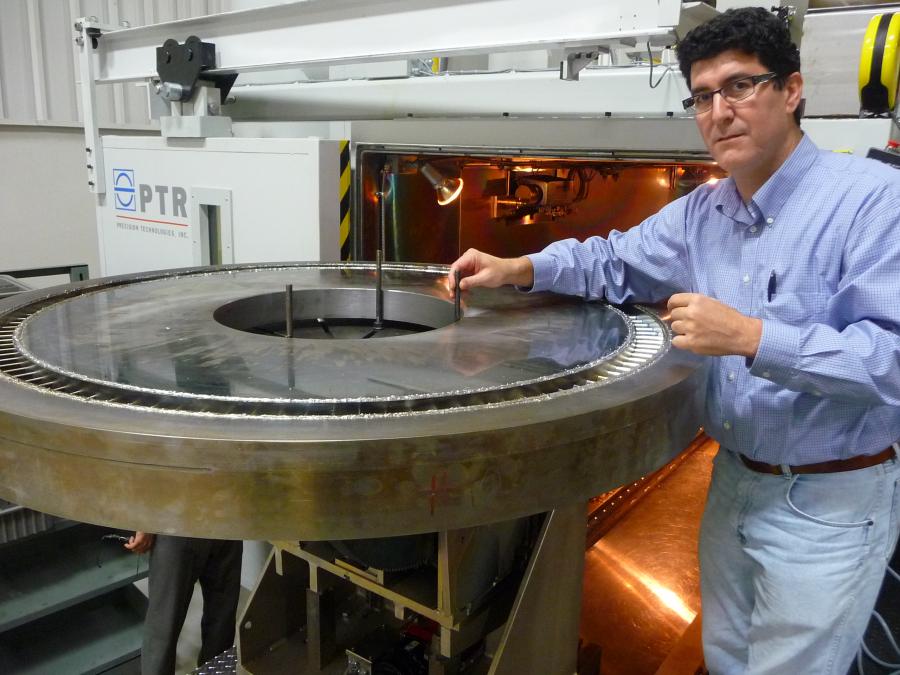

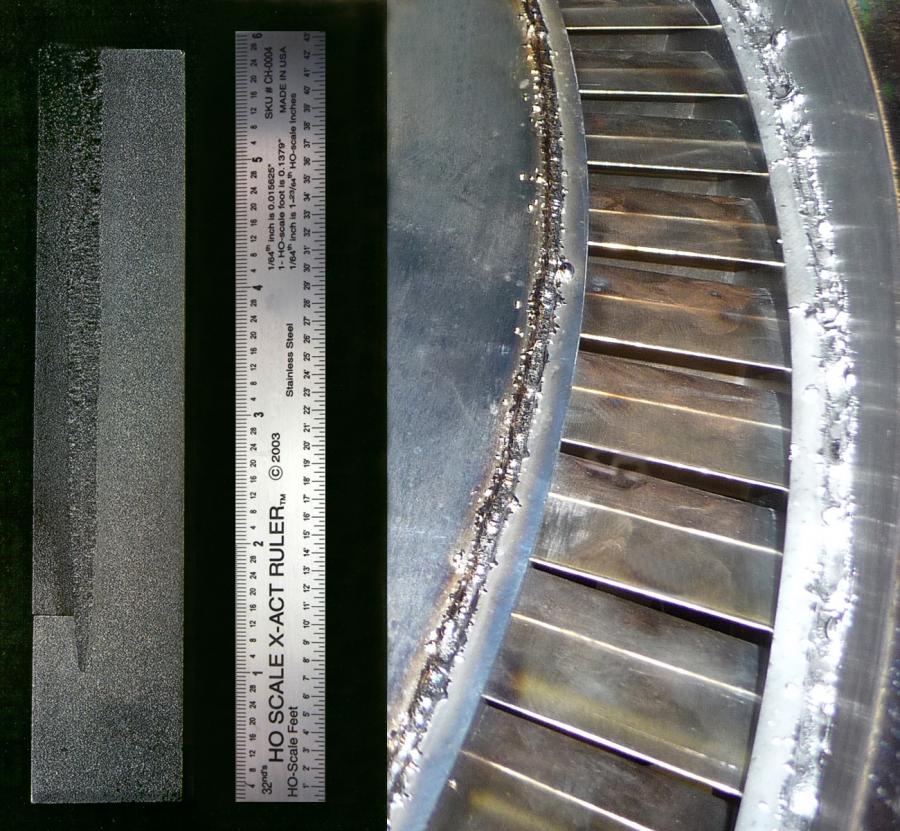

Combustion Chamber Cover Welding

In power generating gas turbines, multiple combustion chamber covers are used to create fuel/air mixtures and distribute them through machined channels to injection nozzles. Each cover assembly has multiple injection nozzles and channel covers that require welding. The preferred process for joining combustion chamber parts is electron beam welding. In this application, characterized by high levels of thermal cycling, the performance of EB welds is superior to other welding techniques.

Description:

2.5 ft diameter Forging

with Milled Channels

Material(s):

304 Stainless Steel

Joint Geometry:

step joint

Weld Depth:

0.500 in.