Do you have a new weld application you are developing? Having material processing issues? Need help with quality requirements?

Leave it to PTR!

Let PTR's experienced contract welding department provide assistance developing your EB weld process. Save time and avoid potential pitfalls - call PTR first.

- Weld Specifications

- Quality Requirements

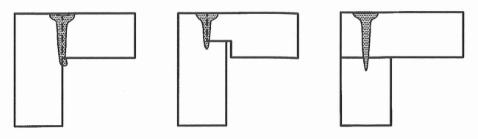

- Joint Design

- Material Selection

With decades of electron beam welding experience, PTR can help develop and qualify weld processes according to your requirements.