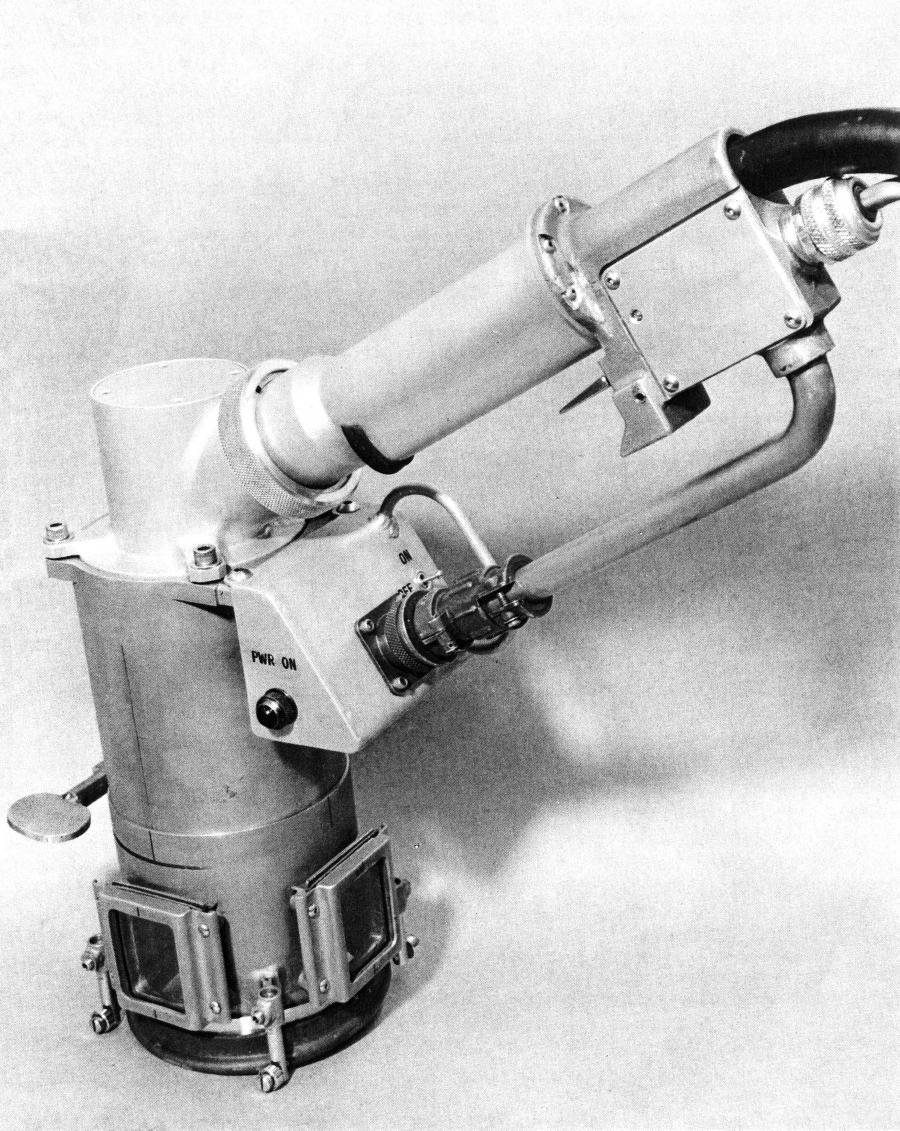

Hamilton Zeiss:

PTR’s involvement with electron beam welding dates back to 1959, when United Aircraft (now United Technologies Corporation) had plans to diversify its existing aerospace business lines with the addition of a new industrial product line. After extensive research United Aircraft approached the Carl Zeiss Co. of Stuttgart, West Germany, concerning their electron beam equipment. At the time Zeiss had been conducting experiments with their Electron Microscope with the primary purpose of increasing the power limits of the device. In the process they discovered that, as the power was increased, specimens being examined would disappear. With further investigation Zeiss found that by regulating the electrical settings of the instrument at the point where the beam impinged on the specimen, they could make specimens either vaporize or melt and re-solidify as the beam passed over them, thus Electron Beam Welding (EBW), Drilling (EBD) and Cutting (EBC) technologies were born.

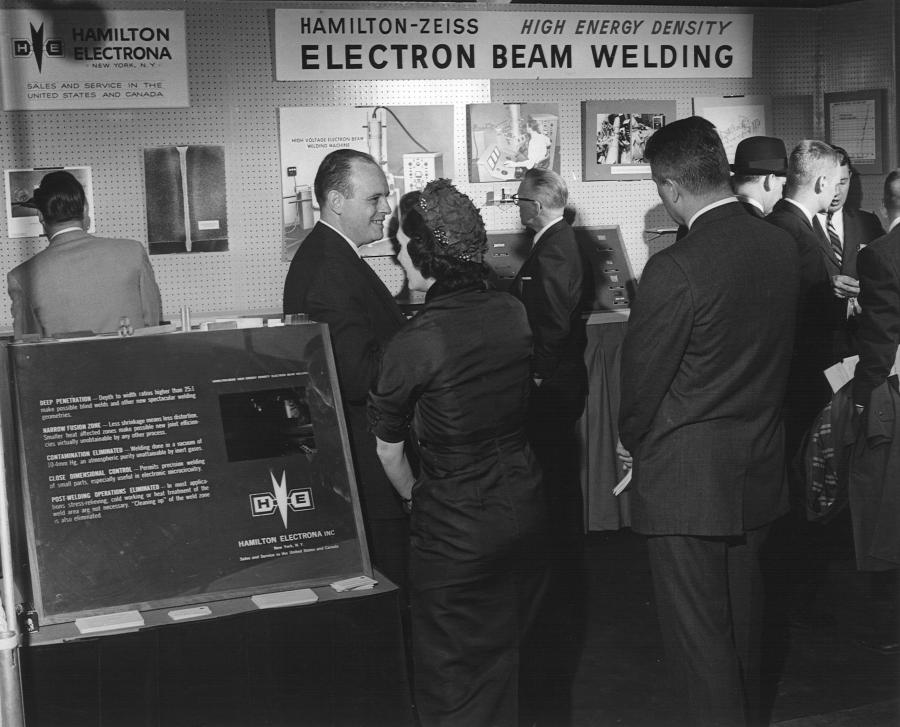

United Aircraft then acquired the North American rights for marketing and manufacturing this type of EB processing equipment in the US from Zeiss. They assigned the responsibility for this task to a newly formed Industrial Product Group that had been established at their Hamilton Standard division in Winsdor Locks, CT. This group initially produced EB equipment under the name Hamilton-Zeiss, while spares and service for the equipment was handled by an agency in the New York area named Hamilton-Electrona. This agency was soon dissolved, and the entire EB business was moved to Hamilton Standard’s (HSD’s) facility in Windsor Locks, CT. One of the first EB units built under this Hamilton-Zeiss partnership was shipped in 1961 to the Rohr Aircraft Company located in California.

Hamilton Standard:

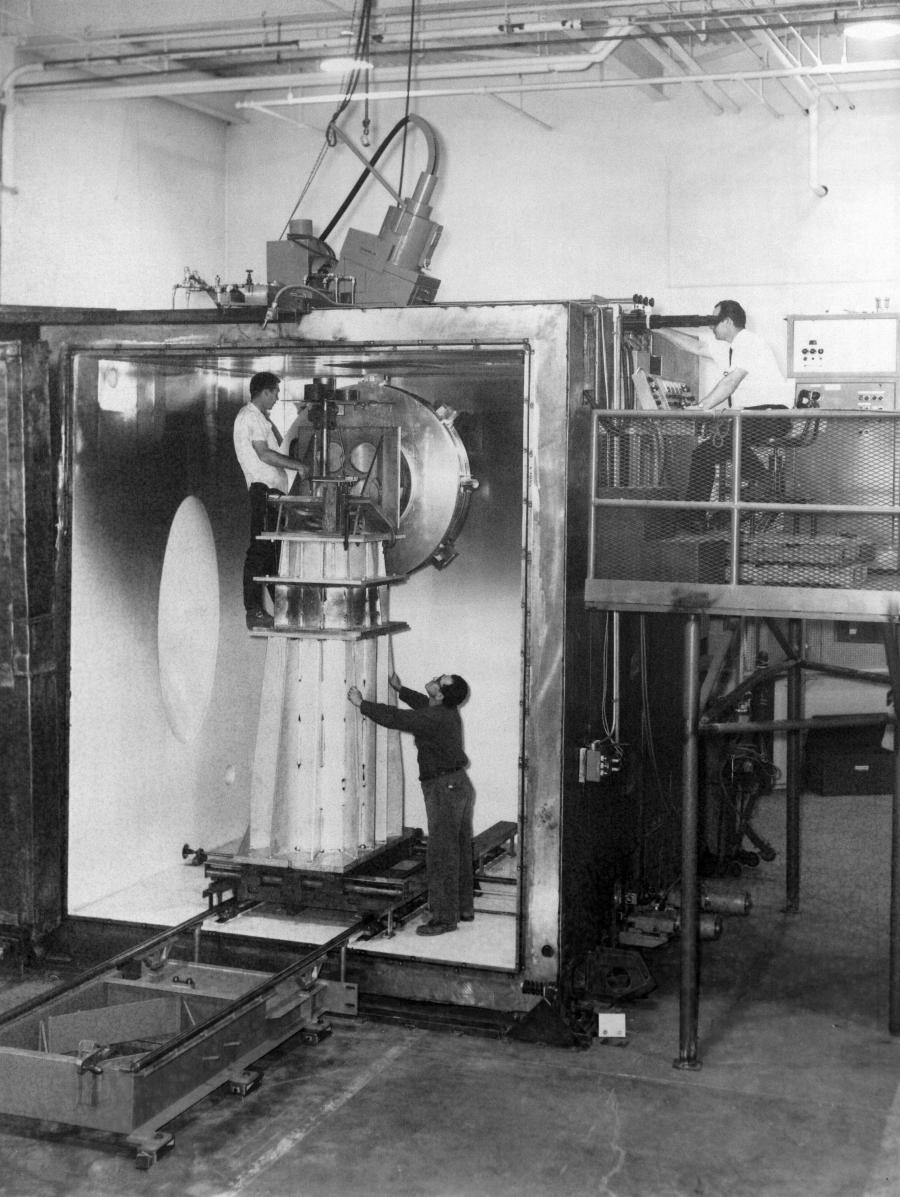

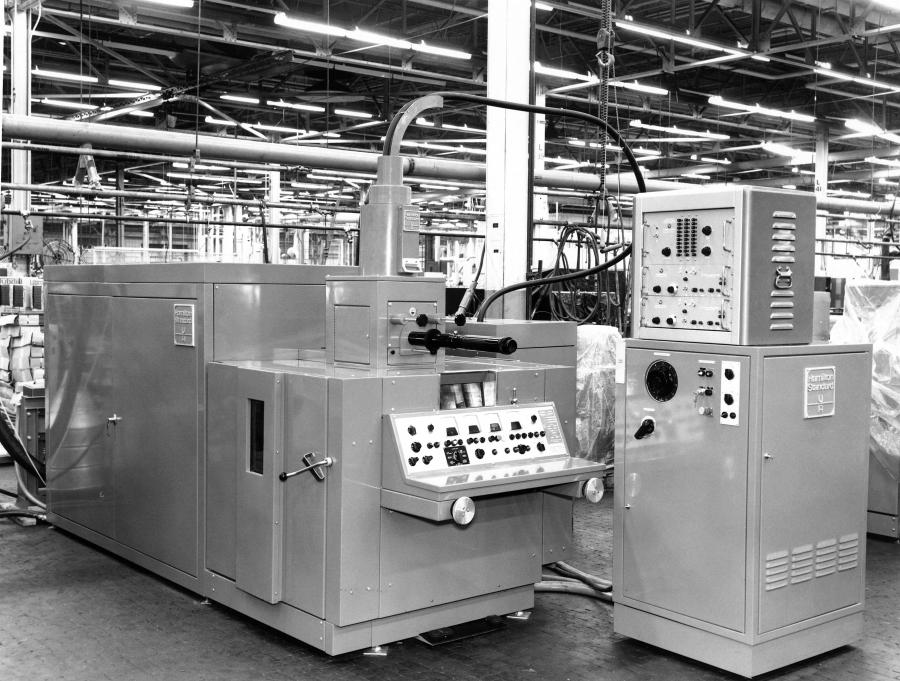

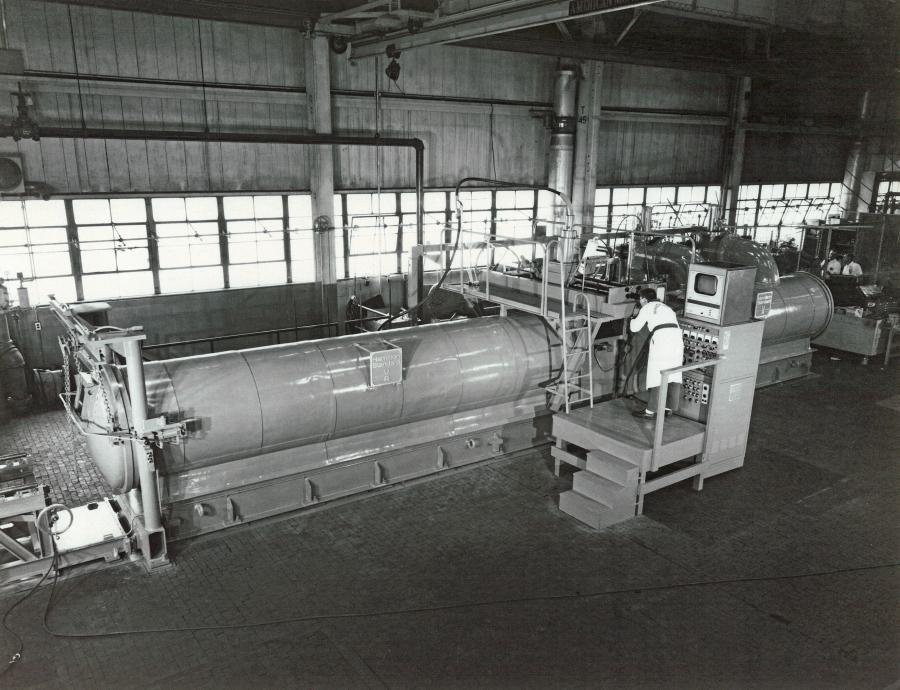

In 1963, after a few years of partnership, Zeiss and United Aircraft agreed to Hamilton Standard’s outright purchase of the worldwide rights to Zeiss’s EBC/EBD/EBW business. Hamilton began both marketing and producing these EB units (primarily for EB Welding) under the Hamilton Standard brand name. Initially, Hamilton manufactured only High Vacuum EB Welder (HVEBW) systems with various size vacuum chambers (dependent on customers application requirements) to meet the EB welding needs of US industries. In the mid-1960’s Hamilton started the developing Partial Vacuum EB Welding (PVEBW) and Non-Vacuum EB Welding (NVEBW) types of electron beam welding machines. These rapidly became very popular in the automotive industry and other industries requiring high production rates.

Toward the end of the 1960’s Hamilton entered into marketing and manufacturing license agreements with Nippon Electric in Japan, Hawker Siddeley Dynamics Engineering in England and Leybold-Heraeus GmbH in West Germany- thus providing it with a worldwide EBW machine sales network.